CNC Machining Stainless vs Titanium: Cost, Speed, and Surface Finish

Table Of Contents

Key Takeaways

- Effective methods for streamlined machining processes

- Important considerations for project organization

- Practical examples of applications in various industries

- Frequent obstacles faced in CNC machining

- Concluding insights on choosing the right material

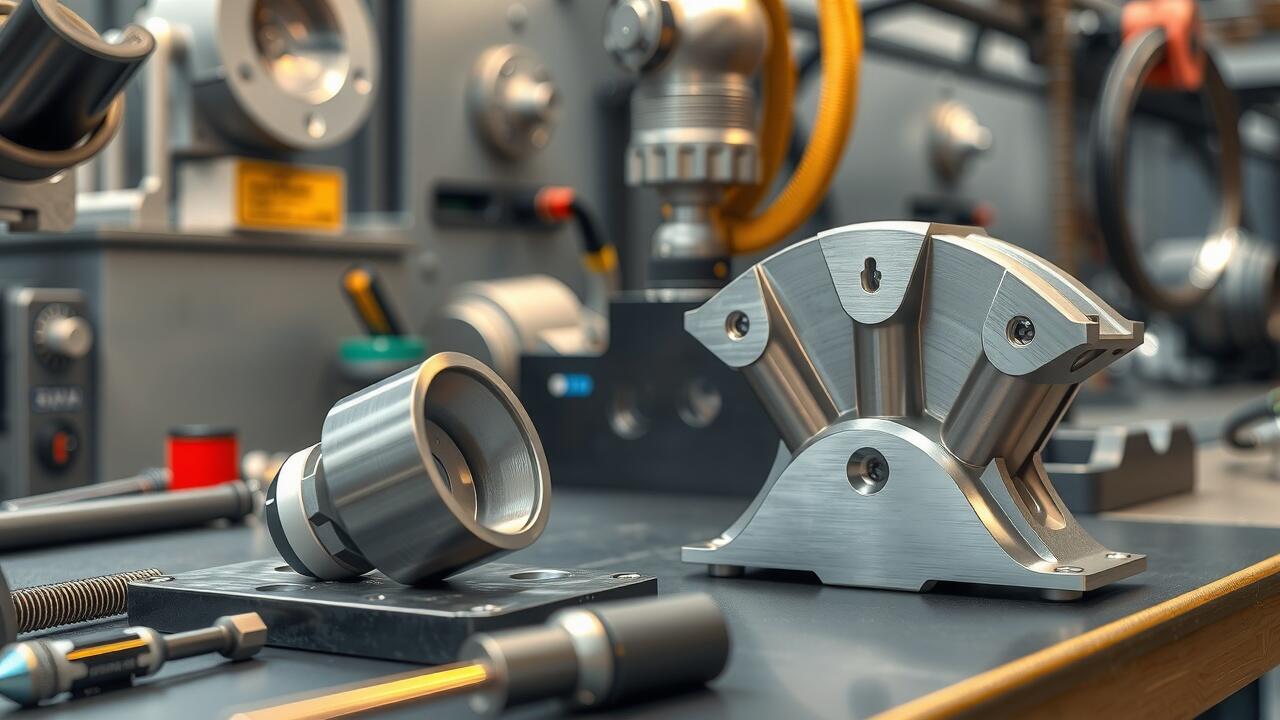

5 Key Strategies for Efficient Machining

Efficiency in machining hinges on strategic choices, particularly when it comes to materials like stainless steel and titanium. For instance, implementing optimized tool paths can drastically improve cut times and reduce wear on tools. Utilizing advanced software for simulation can lead to predictive insights, enabling you to adjust parameters proactively. This not only saves time but also cuts down on material waste, a key factor when dealing with expensive titanium components.

Furthermore, investing in high-quality cutting tools suitable for stainless steel machining is crucial. Carbide and cobalt-tipped tools often last longer and perform better compared to standard options. For those working in high-precision environments, it’s critical to monitor and maintain the equipment regularly. Adhering to best practices, like ensuring proper coolant flow during CNC stainless steel operations, can significantly enhance both surface finish and tool longevity. These small changes in approach can yield big savings and improvements in overall project outcomes.

How Can Proper Tool Selection Improve Outcomes? (Choosing the right tools for each material)

Selecting the right tools for machining stainless steel or titanium can significantly enhance not just efficiency but also the quality of the final product. For instance, using carbide tools for stainless steel machining can increase lifespan and performance due to their strength and heat resistance. Choosing the correct geometry, such as a sharper edge for softer materials, will lead to better chip management and surface finish. Matching the tool’s specifications with the material's properties is key for minimizing wear and maximizing machining speeds.

When it comes to CNC stainless steel machining, the use of appropriate coatings can further improve outcomes. Coatings like TiN or TiAlN enhance tool life by reducing friction and improving heat dissipation. Utilizing advanced toolpaths can optimize cutting parameters for different materials, ensuring that facets such as feed rates and spindle speeds align with the desired finish. For example, implementing a low-speed, high-feed strategy on tougher titanium components can yield better surface quality and reduce cycle times. This tailored approach not only improves efficiency but also leads to substantial cost savings in the long run.

Project Planning

Effective project planning starts with a clear understanding of the material being machined. For instance, stainless steel machining often requires different tooling compared to titanium due to its unique characteristics. Professionals should consider factors like hardness, corrosion resistance, and machining speed when selecting tools and setups. A case in point is a recent project in aerospace manufacturing, where improper tool selection for stainless steel led to longer cycle times and increased wear on machinery—resulting in costly downtime.

Design intricacies can significantly impact machining efficiency as well. Streamlining designs not only simplifies the machining process but can also enhance surface finish and reduce waste. For example, utilizing optimized geometries within CAD software allows for greater precision in CNC stainless steel applications. Implementing design for manufacturability (DFM) principles can lead to shorter lead times and better overall project outcomes. Ensuring that designs consider tooling paths, fixturing, and material flow helps to mitigate potential challenges upfront.

How Can Design Impact Machining Efficiency? (Exploring design considerations for both materials)

Design plays a pivotal role in efficiency when it comes to machining stainless steel and titanium. Simplifying geometries reduces machining time and wear on tools. For instance, opting for rounded edges rather than sharp corners can lead to smoother cutting paths. It also minimizes the likelihood of tool breakage. Engineers often analyze part designs using simulation software to predict machining challenges early, potentially saving time and costs.

Material selection based on design requirements can significantly influence processing strategies. Stainless steel machining often demands different approaches than titanium due to variance in hardness and thermal properties. For example, a complex part that requires intricate features may necessitate more advanced tooling or slower feed rates with titanium, while benefiting from faster cycle times in stainless steel CNC machining. Incorporating features like symmetry and uniform thickness can streamline processes. Prioritizing these factors during the design phase enhances overall machining efficiency and product precision.

Real-World Applications

Manufacturers heavily rely on stainless steel machining for a range of applications. The automotive industry frequently utilizes stainless steel for components like exhaust systems and body panels due to its corrosion resistance and strength. Recent statistics highlight that around 70% of automotive parts are made from stainless steel, a testament to its durability and aesthetic appeal. On the aerospace side, components such as brackets and fittings are often fabricated with CNC stainless steel to ensure they can withstand harsh environmental conditions while maintaining a lightweight profile.

On the other hand, titanium has carved out a crucial niche in industries like medical and aerospace, where performance and weight matter. In the medical field, titanium's biocompatibility makes it a go-to for implants and prosthetics. Many orthopedic devices are now manufactured using titanium, as studies show they can reduce the risk of rejection by up to 50% compared to other metals. In aerospace, titanium alloys are used in jet engines and structural components, thanks to their impressive strength-to-weight ratio. These applications underscore the distinct advantages each material brings to the table, shaping the choices of engineers and manufacturers alike.

What Industries Prefer Stainless Steel or Titanium? (Industry-specific examples and case studies)

Aerospace often leans heavily toward titanium for its exceptional strength-to-weight ratio. Aircraft manufacturers use titanium components to reduce overall weight while maintaining structural integrity. For instance, the Boeing 787 incorporates titanium in its wing structure to bolster durability under demanding conditions. This choice not only enhances performance but also helps in fuel efficiency. In contrast, stainless steel machining finds its niche in industries like automotive, where durability and corrosion resistance are paramount. Car manufacturers favor stainless steel for exhaust systems and chassis components, benefiting from its resistance to high temperatures and rust.

The medical sector relies on both materials for various applications. Titanium's biocompatibility makes it the material of choice for implants and surgical instruments. Companies like Stryker utilize CNC stainless steel for tools and devices due to its ability to endure sterilization processes without degrading. Meanwhile, the food processing industry often mandates stainless steel for equipment, given its easy cleaning properties and resistance to chemicals. Choosing the right material not only delivers specific functional advantages but also adheres to regulatory guidelines crucial in these high-stakes environments.

Common Challenges in CNC Machining

Machining stainless steel presents unique challenges, especially when it comes to tool wear and heat generation. For example, when cutting at higher speeds, operators often notice increased tool wear due to the abrasive nature of stainless steel. This can lead to inaccuracies in the finish, which is particularly critical for industries that require precise tolerances, like aerospace or medical device manufacturing. Engaging proper coolant strategies can help mitigate these thermal issues and extend tool life, allowing for better cnc stainless steel outcomes.

Titanium, though lighter and strong, introduces its own set of hurdles, including chip formation and a tendency to gall. When machining titanium, manufacturers often experience poor chip evacuation, resulting in a higher likelihood of re-cutting chips, which can compromise both surface quality and tool integrity. Adopting a higher flute count on end mills paired with slower feed rates improves chip removal and maintains surface finish in such cases. Learning from industry case studies can lead to improved techniques and more effective machining processes, ensuring that both materials are handled efficiently within their respective tolerances.

How Can You Overcome Machining Difficulties? (Troubleshooting typical issues)

Machining difficulties can crop up when working with materials like stainless steel. A common issue is tool wear, especially when using the wrong end mill or insert. The hardness of stainless steel machining demands specific carbide or high-speed steel tools designed for durability. If your tools show significant wear after just a few parts, it's time to reassess and substitute them with options better suited for the alloy. Effective monitoring of tool life through regular inspections can lead to improved efficiency, as changing tools at the right time reduces downtime.

Another challenge involves managing chip removal and heat generation. Poor chip removal can lead to recutting, which negatively affects surface finish and tool life. For instance, using a flood coolant system can not only keep the machining area clean but also manage temperatures efficiently during stainless steel CNC machining. Adjusting feed rates and spindle speeds can optimize chip flow and cooling. These proactive measures allow for a smoother operation and enhance the final quality of the components produced.

Final Thoughts on Material Selection

Material selection greatly influences the overall success of a machining project. When considering stainless steel machining, factors such as tensile strength, corrosion resistance, and cost play pivotal roles. For example, aerospace applications often rely on high-end stainless steel alloys for components due to their durability and adaptability in harsh environments. Similarly, industries that require a lightweight yet strong material may lean towards titanium, despite its higher cost.

Understanding the benefits and limitations of both materials can streamline production processes. For instance, stainless steel CNC machining can achieve faster cycle times on standardized parts due to the prevalence of tools and techniques specific to this metal, often allowing for cost-effective production runs. Meanwhile, titanium machining might require specialized tools and longer setup periods but rewards operators with superior performance in terms of strength-to-weight ratio in critical applications like medical implants. Balancing these factors ensures your approach to machining is both efficient and effective.

FAQS

What are the main differences between CNC machining stainless steel and titanium?

The main differences lie in cost, machining speed, and surface finish. Stainless steel is generally more affordable and easier to machine, while titanium offers superior strength and corrosion resistance but can be more challenging and expensive to work with.

How does tool selection affect the machining process for stainless steel and titanium?

Proper tool selection can significantly improve machining outcomes. Choosing the right tools ensures efficient cutting, reduces wear, and enhances surface finish for both materials, which is crucial for achieving the desired results.

What should I consider during project planning for machining these materials?

When planning your project, consider factors like material properties, desired tolerances, production volume, and cost constraints. Each of these elements can influence the choice between stainless steel and titanium, as well as the overall machining process.

Are there specific industries that prefer one material over the other?

Yes, certain industries have a preference based on the unique properties of each material. For example, the aerospace industry often favors titanium due to its lightweight and strength, while the automotive industry may lean towards stainless steel for its cost-effectiveness and versatility.

What common challenges might I face when machining stainless steel or titanium?

Common challenges include tool wear, heat generation, and achieving the desired surface finish. Each material presents its own difficulties, but with the right strategies and troubleshooting techniques, you can overcome these issues effectively.